Masks! Masks! Masks!

Every healthcare worker has been pleading and begging for them, and politicians are proclaiming; my kingdom for a mask!

In some states, you cannot walk into a grocery store or any other essential business without one. People are doing anything to get a hold of an N95 mask or just wrapping a scarf around their face. With overrun hospitals facing an acute shortage of masks, many people are coming up with creative ways to help fill the void.

One construction business owner from a town in southeast Pennsylvania, outside of Philadelphia, found himself out of work as a result of the stay-at-home order. His business shut-down, Paul Michos, from his modest home in Broomall, wanted to do something, anything, not only to keep busy but help in this crisis. As a Greek-American, Paul took to heart the Greek word, philotimo, considered to be the highest Ancient Greek virtue. Hard to translate and describe, philotimo is best defined as doing something good.

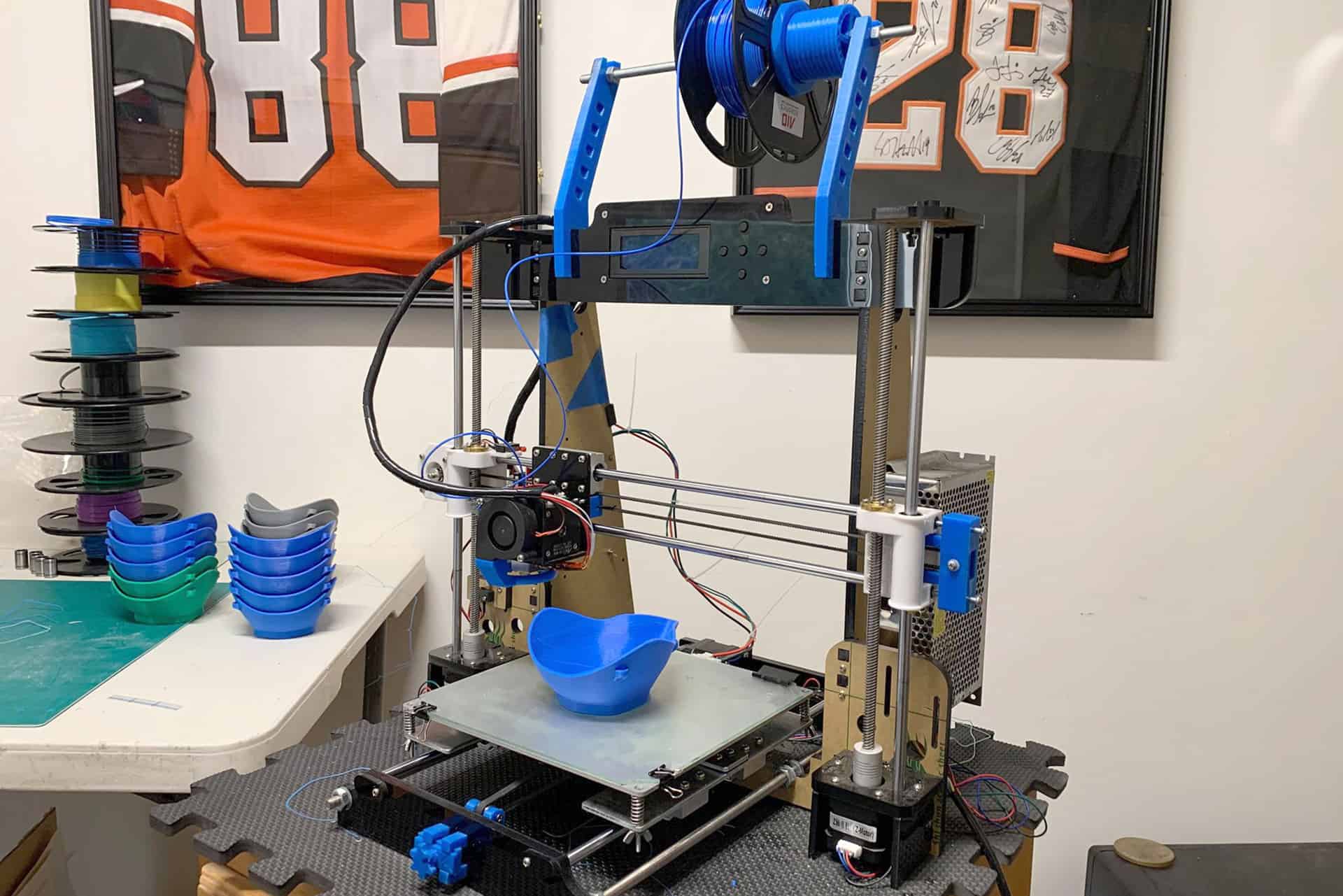

“When my construction business came to a halt, I wanted to find a way to stay productive and help,” says Michos. Watching the news and social media led him to surf the internet, where he saw the website “The Montana Mask.” The Montana Mask is a highly effective filtration mask. It’s 3D printable and, what’s best, the design files are free for public use. It can also be sanitized and reused. Although not approved by the FDA or NIOSH, the mask has been rigorously tested. “The doctors I had spoken with said, because of the circumstance, it would be good enough to work with,” recalls Michos.

What was even better was that the level of protection is customizable, depending on which material you use for the filter. The website also listed a link to another company working with Montana Masks that was producing and supplying filters for the masks. Michos downloaded the information, did some additional research on FDA approved masks, filters, and how to construct them.

Michos said, “I tackled this project like any construction project I have been involved with.” He started testing his 3D masks first. The process was slow and required software tweaks, which he was able to obtain from others via the internet. Each mask took four hours to make and assemble with filters and totaled $1.60 each.

It may not sound like much, but Michos wanted to make sure he could supply several months’ worth of filters per mask, and that would cost him more than $1,000. That’s where he came up with an online fundraising campaign to help with the purchase of the materials.

He set up a campaign on Facebook with a goal to raise $1,000, but twenty-four hours later, he was surprised to find out that he had exceeded the $1,000. The overwhelming support from his friends and social media had raised $3,735.00. He could now make even more masks then he expected. Michos quickly went to work in his home office, printing and assembling each mask with gaskets and filters. The tedious four-hour process to produce each mask was intense. To help, he reached out to a friend, Nick Sagos, owner of Pizza Heaven in Upper Darby, who also owned a 3D printer and wanted to get involved. A few weeks later, more than 130 masks, with two months supply of filters for each, were assembled, packaged, and ready to go.

As Michos continued to share information about mask-making online, many were inspired and began to make masks as well. “I started to post and share information with people online. People started to contact me and ask for advice on how to do it,” said Michos. “A guy from Atlantic City, New Jersey, reached out to me on how to set it up after seeing my posts on Facebook. He later contacted me and said that he bought a 3D printer and started making them as well,” added Michos.

With the initial 130 plus masks and filters, Michos was ready to distribute them. “I divided the first one hundred between the University of Pennsylvania and Temple Hospitals. The next thirty I sent out to some nurses that contacted me online requesting the masks and the rest went to people I knew in the medical field,” said Michos. Delivery of the masks went out this past Tuesday.

But that is not the end of the story, and Michos’ Greek virtue of philotimo continued.

After all, Michos had done to help out the doctors and nurses at his area hospitals, he found himself with about $700 left from the online fundraiser. He could have done anything with the extra money, including keeping it since he had also spent money out of pocket on the project. But he didn’t. He had thought it through. Michos went to a local pizzeria owned by a cousin and asked to purchase as many pizzas as he could with the $700, to feed the healthcare workers at the hospitals. His cousin, at first, refused to accept the money, stating that he, too, wanted to help.

Michos, being a small business owner, understood about keeping businesses going. He explained to his cousin that by purchasing those pizzas from his store, it would help keep the store open and the workers employed.

The next day, Michos, and a group of friends, loaded a truck and delivered those masks and pizzas to the medical administrators that met them outside the hospitals. The administrators were overwhelmed with gratitude, and Michos wanted to hug and to thank them for what they were doing, but he couldn’t. “Even though I couldn’t see the smile on their faces. I saw it in their eyes. And that made it all worth it.”

There are many, many stories out there like the one of Paul Michos. Most will never be made known to the public, but the local healthcare workers who benefited from having someone with a little heart and ingenuity will always be remembered by them far after this crisis is over. A Greek-American, with philotimo, did good.

Written by Eleftherios Kostans and Harry Karapalides